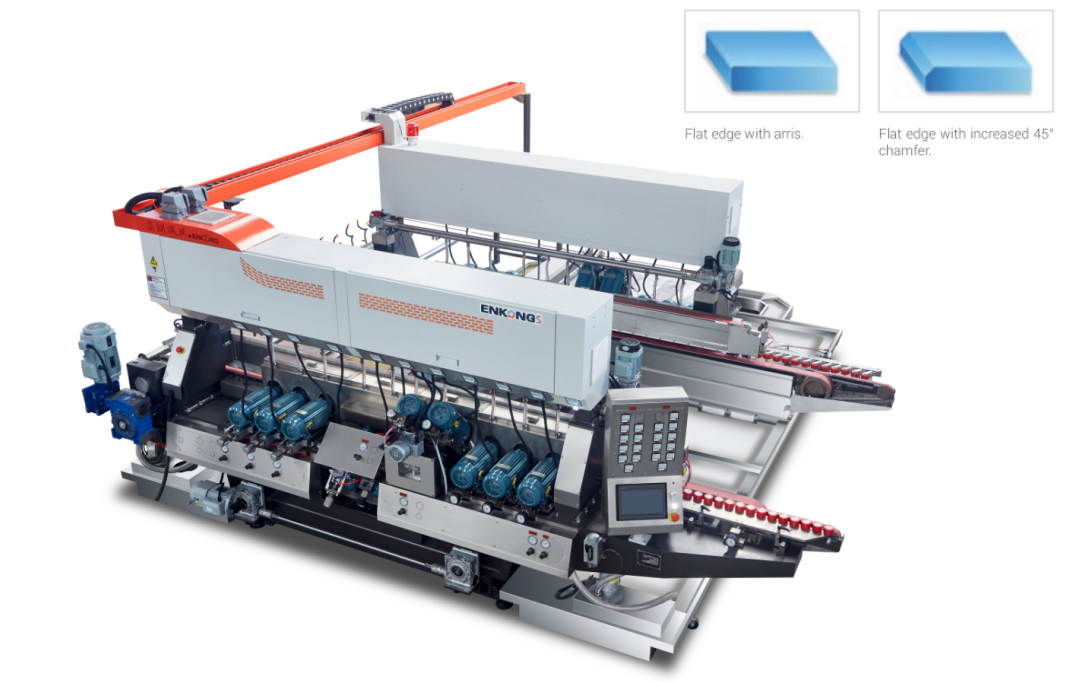

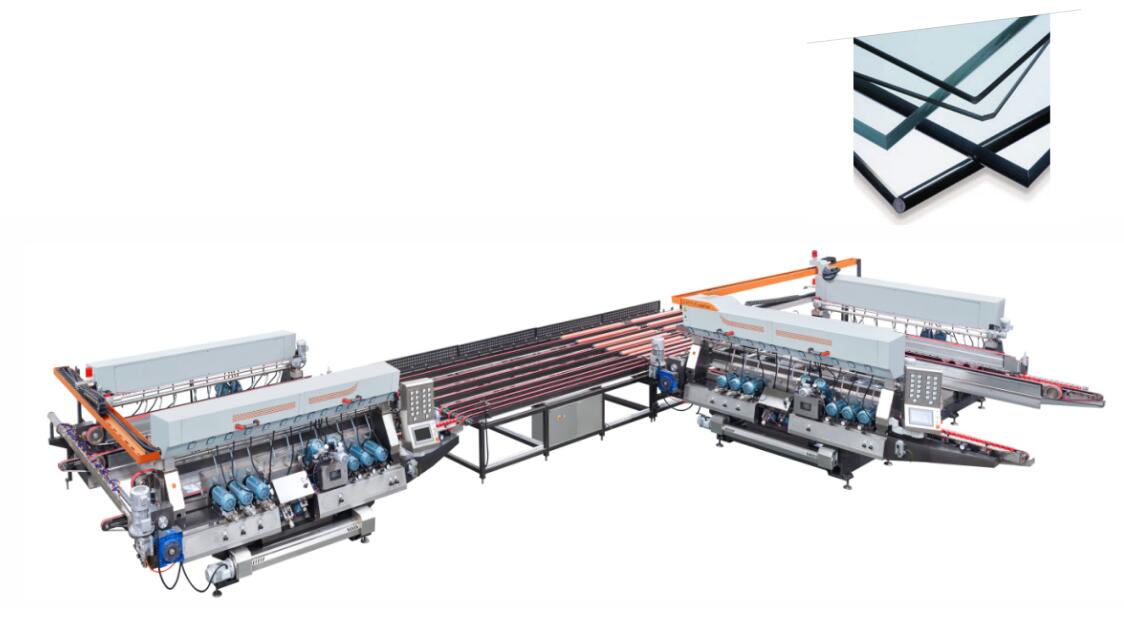

SM2015 Vetro dritto con doppia bordatura standard

Macchina Per Vetro Da Costruzione

Informazioni generali :

1. La linea di produzione dei bordi inizia sulla molatrice 1# e la tavola di trasferimento viene automaticamente ruotata sul lato lungo della rettificatrice 2#.

2. La velocità di elaborazione è 1-15 m/min.

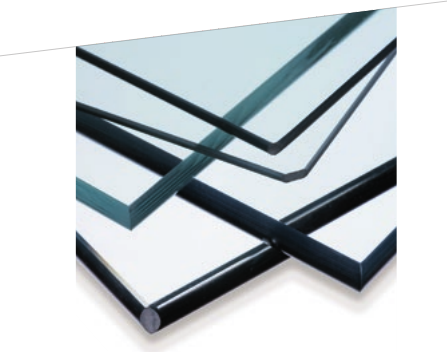

3. Sistema di controllo PLC per impostare i parametri di elaborazione tramite l'interfaccia del monitor per completare l'elaborazione in una sola volta.

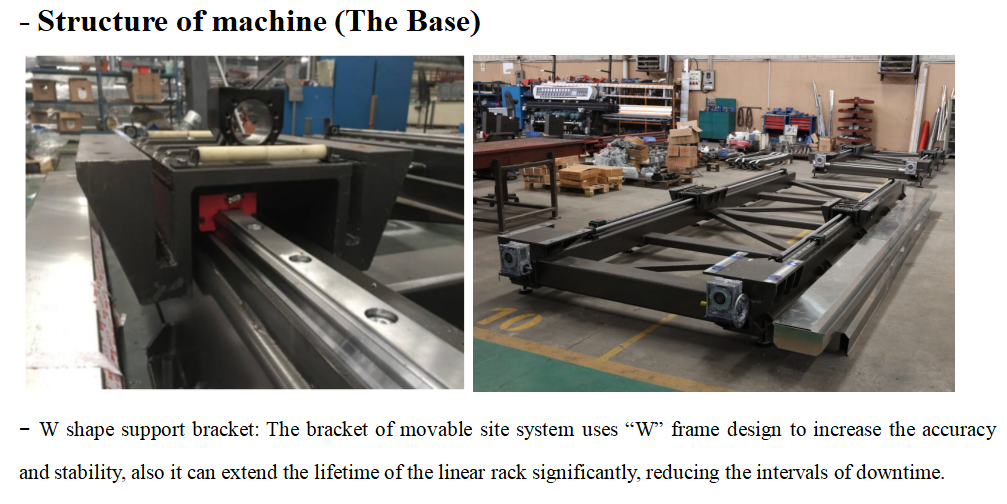

4. La struttura di base stabile e solida contribuisce a un sistema di regolazione della larghezza preciso e veloce.

5. La trasmissione principale ha adottato una cinghia di distribuzione (di marca italiana) ed è dotata di controllo della velocità del motore a frequenza variabile.

6. Secondo il concetto di progettazione modulare, la macchina a doppio bordo dritto può essere dotata di dispositivi di lucidatura potenziati e di eliminazione a bassa emissione.

7. I mandrini di lucidatura possono essere selezionati con lucidatura pneumatica o lucidatura ad alimentazione automatica che migliora la qualità della lucidatura e riduce l'intensità del lavoro dei lavoratori.

8. Nella macchina è possibile trovare funzionalità di sicurezza come il meccanismo di protezione della fune di sicurezza per proteggere l'operatore e il personale di manutenzione.

9. L'intera linea ha una struttura compatta, prestazioni stabili e affidabili, un alto grado di automazione e un'elevata efficienza produttiva.

10. È la migliore macchina di supporto per la lavorazione del vetro su larga scala per mobili e decorazioni architettoniche.

11. Può essere abbinato a linee di produzione come laminazione, stampa e tempera.

1. Vite a ricircolo di sfere (regolazione della larghezza): Taiwan HINWIN/TBI/PMI

2. Guida lineare: Taiwan HINWIN/TBI/PMI

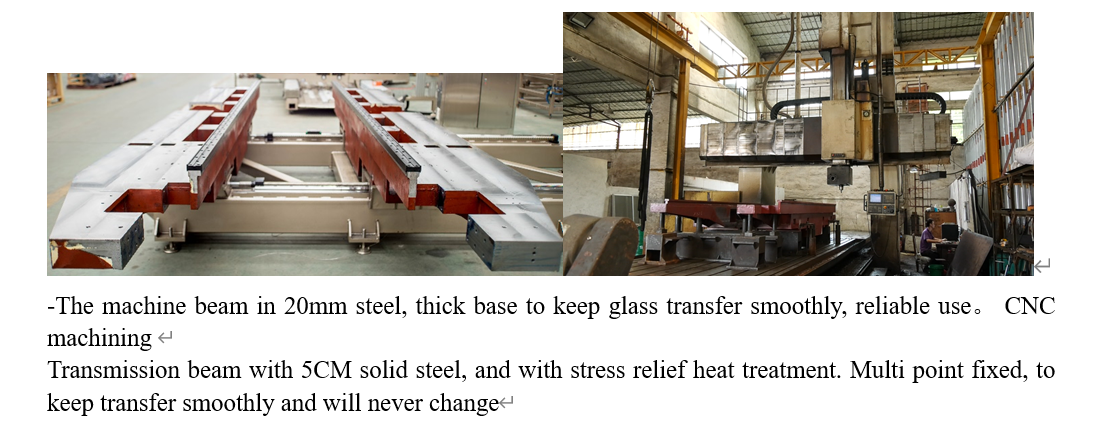

3. base, ponte mobile e fisso, piastra trasportatrice: saldatura di piastre in acciaio di alta qualità dopo la finitura del trattamento termico

4. Materiale del serbatoio dell'acqua: acciaio inossidabile SUS201

5. Cinghia di distribuzione: Megadyne, Italia

6. Funzionamento: PLC + controllo touch screen. Controllo computerizzato PLC completamente automatico, interfaccia intuitiva touch screen, facile da usare.

Linea di produzione:

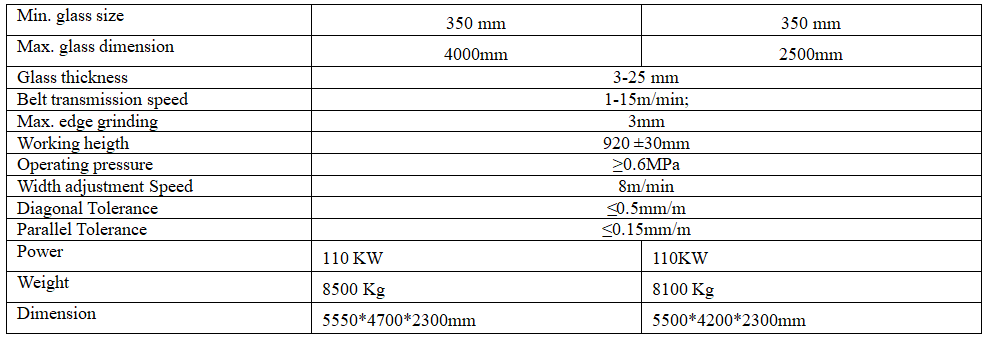

Specifica tecnica:

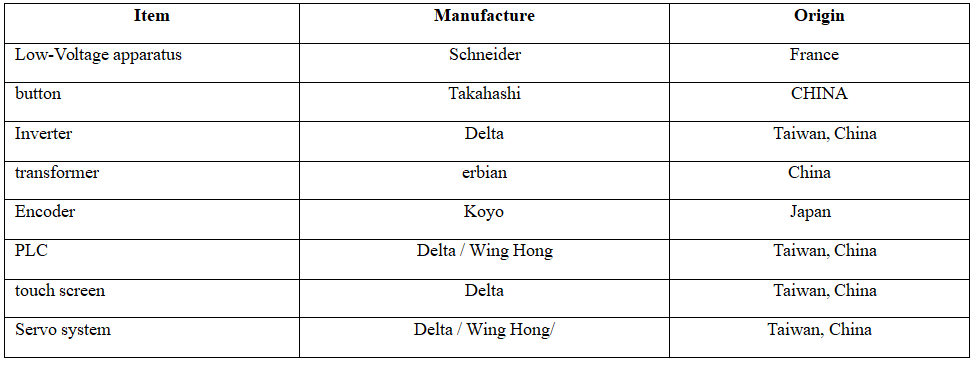

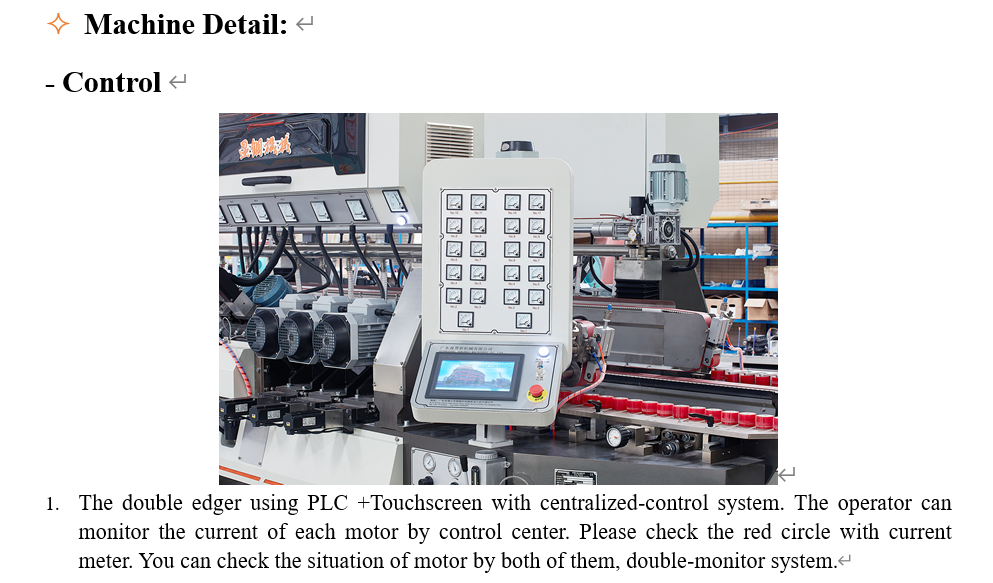

Parti elettriche:

Configurazione delle ruote:

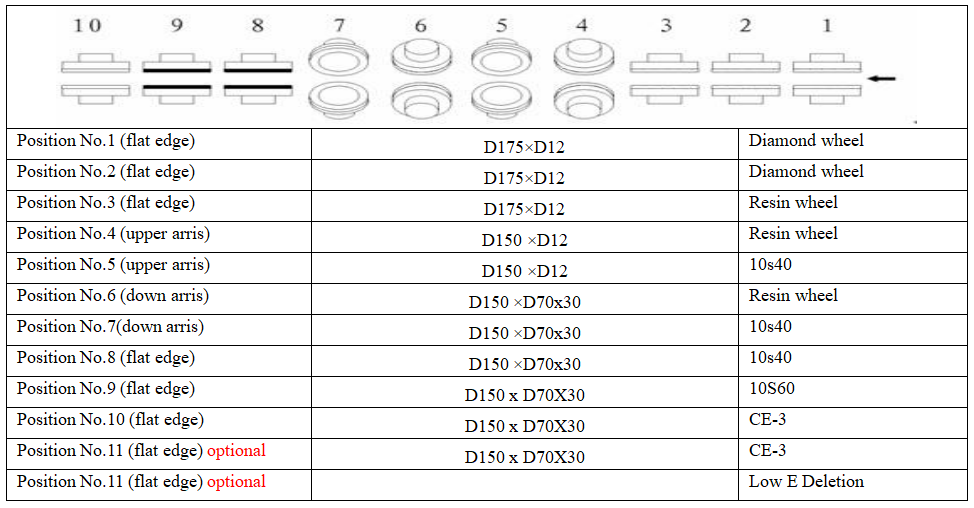

Campione di vetro:

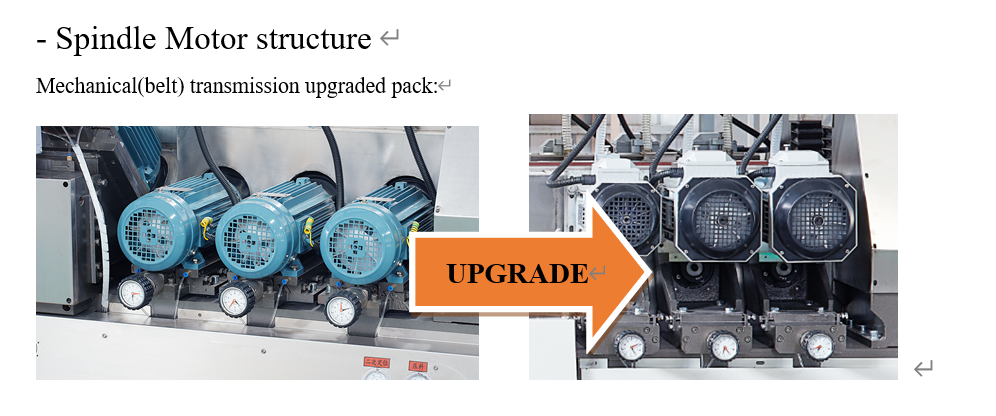

- Il manicotto dell'albero della scatola del cambio principale adotta una struttura a manicotto, utilizzando cuscinetti a rulli ad alta precisione, funzionamento stabile e affidabile, lunga durata, riduzione dei costi di manutenzione. Come opzione è disponibile anche la trasmissione del servomotore.

1. Modello standard: il primo motore ABB ad alte prestazioni adotta 3 kW. All'interno della parte scorrevole adotta il dado in bronzo con asta a vite di regolazione per ridurre lo spazio, più flessibile e durevole.

2. Trasmissione meccanica (a cinghia): con trasmissione meccanica a 4200 giri/min tramite cinghia. Rotazione albero mandrini a 4200 giri/min. L'albero può tollerare un massimo di 12.000 giri/min, utilizzando tuttavia solo 1/3 della capacità di velocità totale. La velocità di lavorazione è di 15 m/min con lucidatura. La capacità di macinazione è migliorata

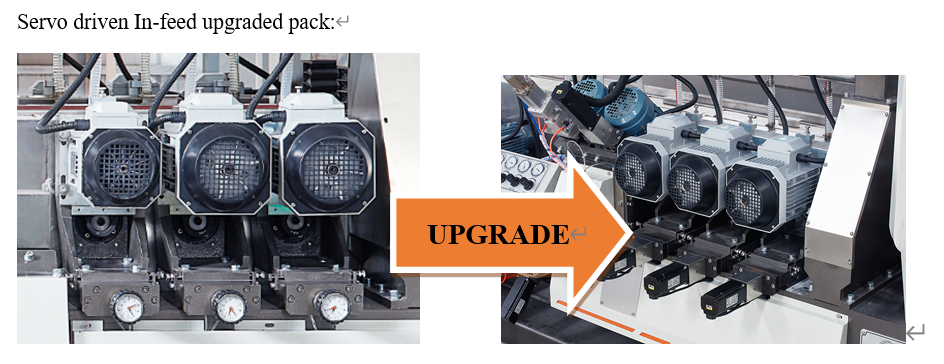

3. Trasmissione meccanica (a cinghia) con disposizione di alimentazione servoassistita: regolazione della ruota completamente automatica. Calcolo preciso tra ruota e materiale. Evita la macinazione irregolare causata da errori umani. Passaggio al livello di automazione successivo.

1. Configurazione del motore:

- Motore del trasportatore: motore a frequenza variabile 2,2KW

- Motore trasportatore a rulli 1: motore a frequenza variabile 1,5KW

- Motore trasportatore a rulli 2: motore a frequenza variabile 1,5KW

2. Parametri tecnici:

1 | Dimensione minima del vetro di trasferimento: | 350 mm*350 mm | |

2 | Dimensione massima del vetro di trasferimento | 2500 mm*1500 mm | |

3 | Spessore del vetro di trasferimento | 3-25 mm | |

4 | Potere totale | 5,2 kW | |

5 | Dimensioni | 8100 mm * 2900 mm * 1000 mm | |

Nota:Quando cambia la dimensione del vetro di trasferimento, le dimensioni esterne cambiano di conseguenza. | |||